From Technical Innovation to Customer Value

This case illustrates a complete product development process from the inital idea and mission to the launched product.

In early spring of 2019 me and the software product team I belonged to as a UX designer found ourselves in a rather inconvenient situation.

The IoT project for our employer - a large manufacturer of general lab equipment like centrifuges, pipettes or liquid handling automates - had just finished but left the new business unit for digital products a little bewildered. The software that had started out as a technical innovation study provided many useful features and functions and the web interface was responsive and nice to look at, but it was

not considered as a product: something that addresses a real problem or need of our customers.

After this setback, everyone in the company seemed insecure whether we as a high quality hardware manufacturer would be able to take the turn and become a digital player in the lab.

Incited to prove them wrong and show that we are capable to develop a great product, our product team requested some budget and a few weeks time, to pitch a product idea.

1. Ideation

We already had the technical infrastructure from the recent IoT Project to be able to connect a wide range of different laboratory devices to our cloud. Based on assumptions and experiences of our internal domain experts, we developed different product ideas that imagined would serve specific personas with with specific problems. We formulated a hypothesis for each product idea to be validated or falsified in a customer workshop to be set up in the next step.

Hypothesis 1:

It costs a lot of time to find out, which device in which lab is used by which colleague at a certain time and to locate and inform people that they should make room for the next one. This is a big issue for our customers.

Hypothesis 2:

It’s a huge pain for our customers, that device booking currently takes place paper based. It is time consuming having to walk to each instrument to book it and to update times if necessary. Thus the bookings are often not kept up to date and do not serve as a reliable source of information.

Hypothesis 3:

It is a problem that you cannot locate your sample within those large freezer without opening the doors to take a look inside. Leaving the doors open to search your samples will increase the temperature inside your freezer quickly and eventually lead to a nerve-wrecking alarm.

2. Validation

To validate the hypotheses we had formulated for the different product ideas and to find out which ones were the most pressing problems, we organized a workshop with 12 customers and used user journey mapping to get a clear and unbiased picture, where customers see big issues.

By the end of the workshop, the problems we had anticipated were real problems, but the most important one - documentation - had not even been on our radar.

To dive deeper into this topic and generate quantitative data, we started a survey, asking our customers how much time lab personnel actually spent on documentation.

“40-50% of working time is spent on documentation.”

3. Our Goal:

reduce manual documentation time by 80%

Frankly, that is a bold number, but facing such a huge problem that concerned a large part of our customers and beeing aware, that this issue can be adressed by consistent use of digital tools along the entire process - from defining the „workflow“ to allocating devices and tracking the actual execution, we were absolutely convinced that it is possible to save a huge amount of manual documentation time.

4. The Product Concept

In my role as senior UX concepter, it was my responsibility to develop a product concept.

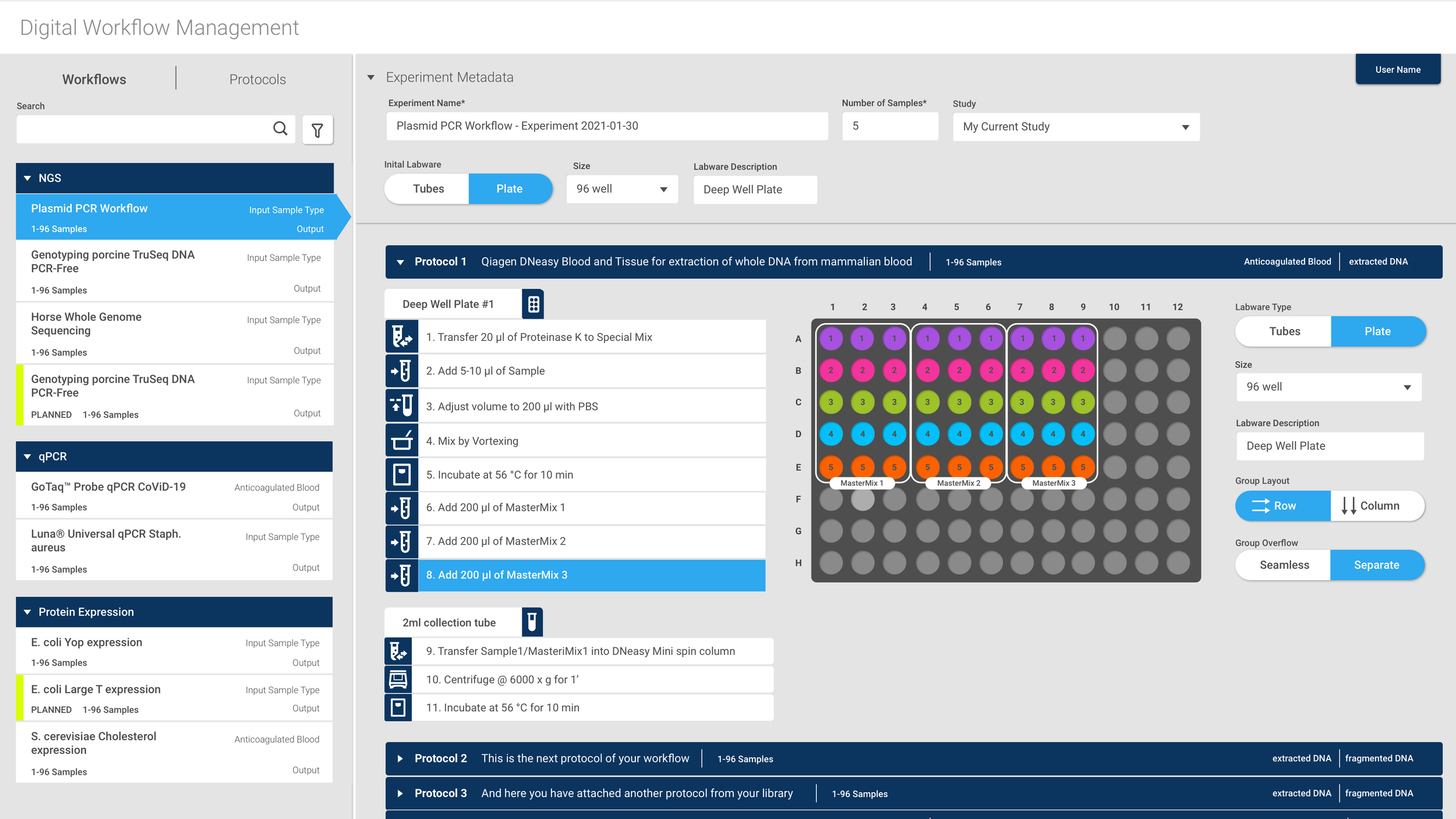

Based on the insights on gains and pains and the user journey outlined in our customer workshop, first wireframes were developed to illustrate the information architecture, interaction beween the different parts of application and navigation concept, as well as the allocation of functionality and features.

As for complete tracking and continuous documentation, the correct flow of information and the integration of the IoT devices is crucial, a large part of the concept development was done in cooperation with our software architect. I also gathered constant feedback by the development team regarding technical feasibility of the concept and we also started to involve further internal stakeholders to ensure we do not miss important information on e.g. legal or sales aspects.

5. Strategic Positioning

Our team did extensive competitive research, taking a close look at the pros and cons of existing solutions.

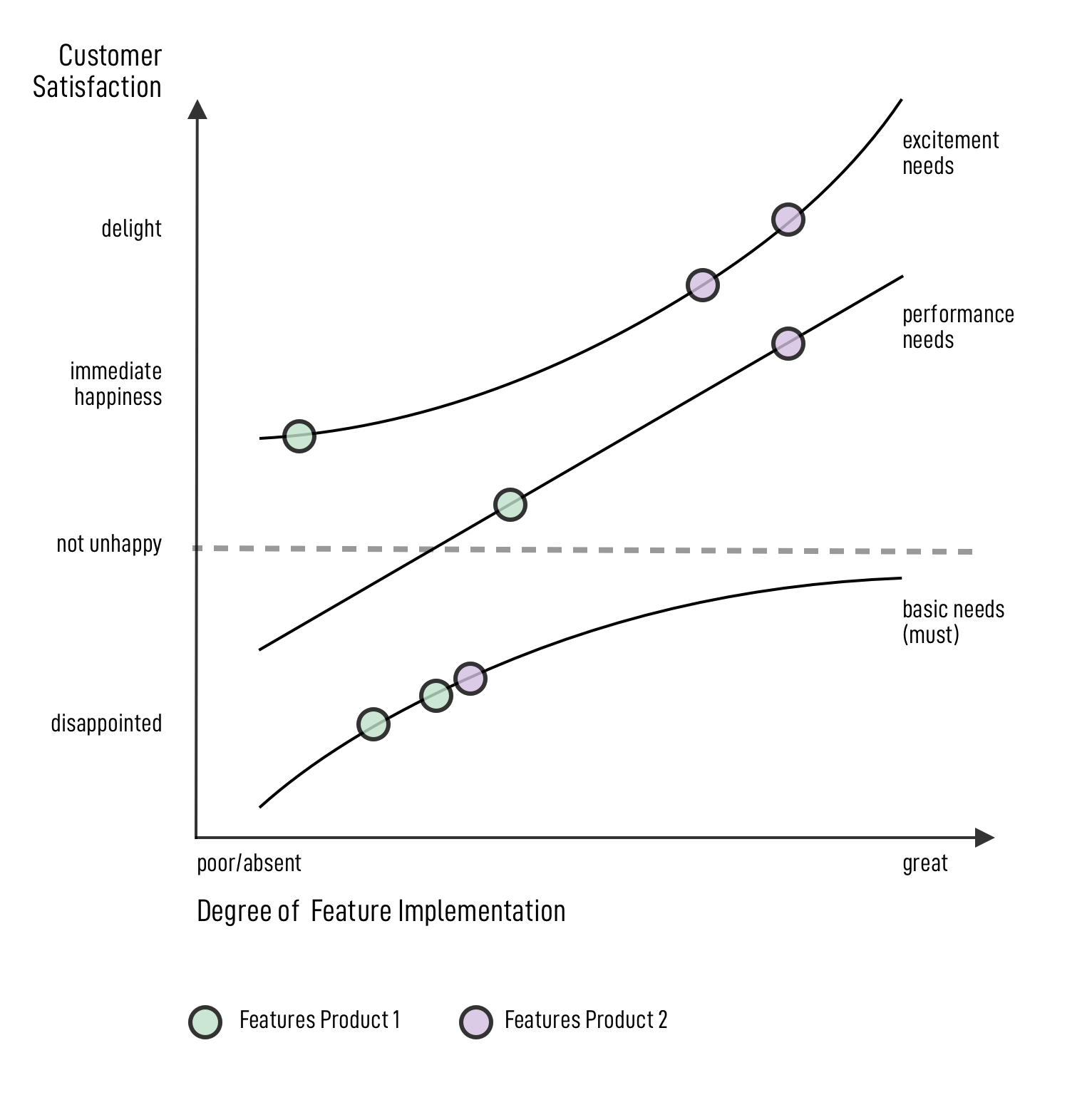

While the developers compared technical aspects and our domain expert reviewed the applications on a functional level, my focus was on the quality of the overall experience using the Kano Model to cluster features into the different satisfaction categories.

We also identified different market segments with specific needs and problems in terms of documenation, so we were able to find a strategic position that fits product we had in mind.

6. Concept Validation

To ensure that the product concept as such is understandable and key functionality as well as purpose becomes clear, we set up a series of customer demos walking them through our click prototype at MVP level explaining structure and functionality.

Right after the demo we conducted a short interview to address the value risk. We asked for feedback if they, as our target users, think this product would help with the problem of documentation and why or why not.

In addition we asked for potential barriers like issues with using mobile devices in the lab, security concerns or any other concerns that could impair the acceptance of the product.

A refined Product Vision

The results of the customer interviews turned out truly encouraging. The concept seemed to be clearly to understand and highly attractive from an experience point of view.

The biggest benefits our customers identified were

time savings due to dramatically less manual documentation work

increased reliability and reproduceability of experiments

easier tracking of samples, reagents and device qualifications (compliance)

“I had actually been looking actively for a solution exactly like this for my lab, that does make use of guided experiments on mobile devices”

(lab manager and workshop participant)

One of our bigger concerns, the acceptance of mobile devices in a lab as biosafety areas, showed to be less of an issue for most customers, and many practices to use these device safely had already been established in many labs.

Based on the input of our customers, we were able to create a refined product vision. With a tangible idea about the scope and the features the MVP would need, our developers were also able to work out a cost estimate.

The Big Pitch.

With a clear product vision, a product concept validated for customer value and technical feasibility plus a precise idea of our strategic positioning, we succcessfully pitched our project to the C-level and were equipped with a two-years development budget for a fully staffed agile project including scrum master, project manager and product owner.